Open vs. Closed Die Forging: Process, Differences, Applications, and Advantages

Multi-chapter guide to open vs. closed die forging describing: what is forging, differences, applications, and open vs closed die forging advantages.

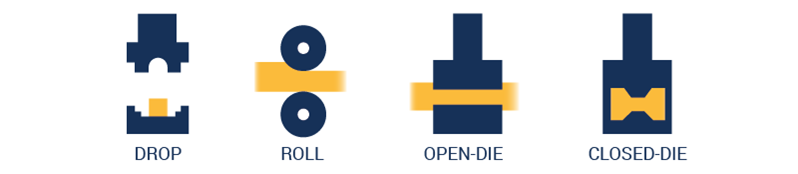

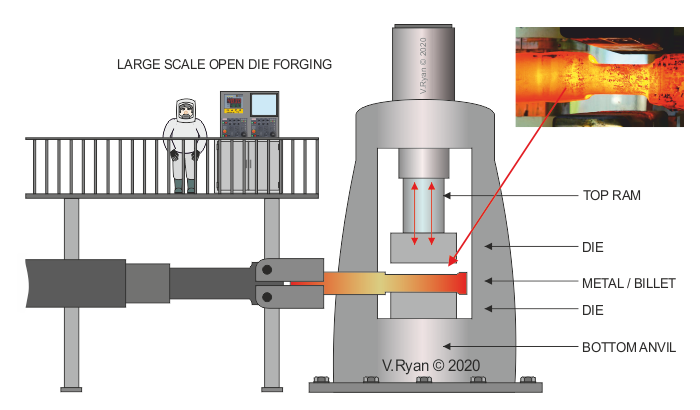

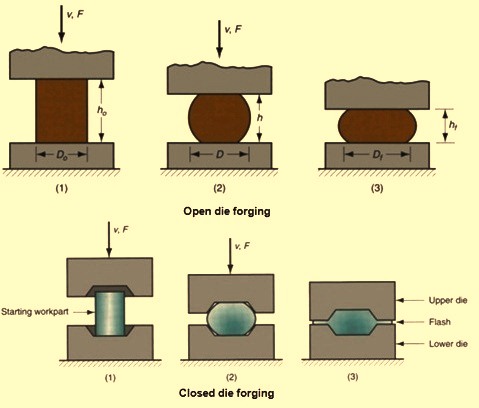

Forging is a process in manufacturing that involves pressing, hammering, or rolling metal objects into various shapes or patterns. Forged parts come in various shapes and sizes and these products include disks and blanks, hollows, forged rings, semi-closed dies, roller rings, bars, hubs, complex shapes, shafts, rotor shafts, eccentric shafts. The diagram below illustrates the steps of the process of forging. The processes will be discussed in greater detail in the other chapters.

Solved 1. What is the difference between open-die forging

Open vs. Closed Die Forgings In Aerospace

Types of Metal Forging Methods

Open Die Forging vs Closed Die Forging

Closed Die Forging - an overview

Processes for Forging of Metals – IspatGuru

Open Die Forging vs Closed Die Forging

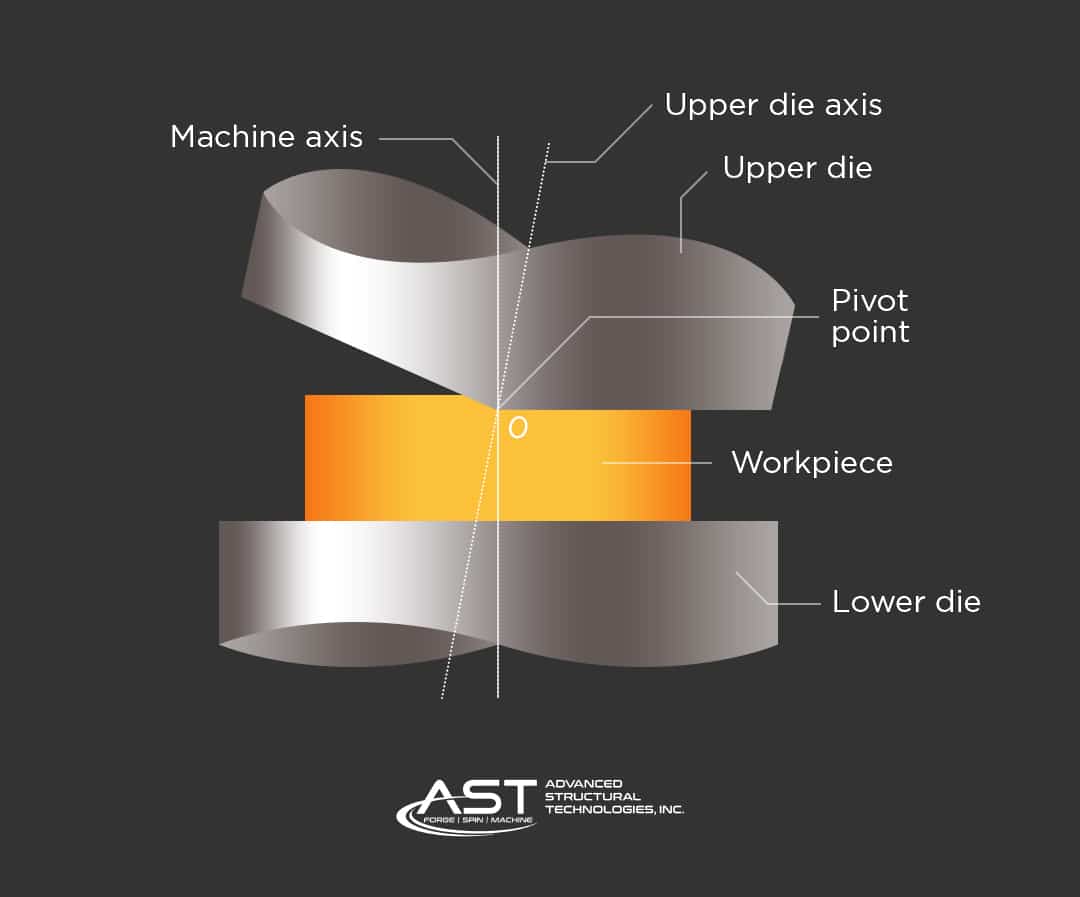

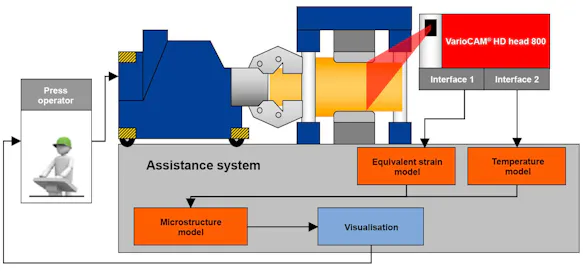

Process Monitoring During Open die Forging

Closed Die Forging

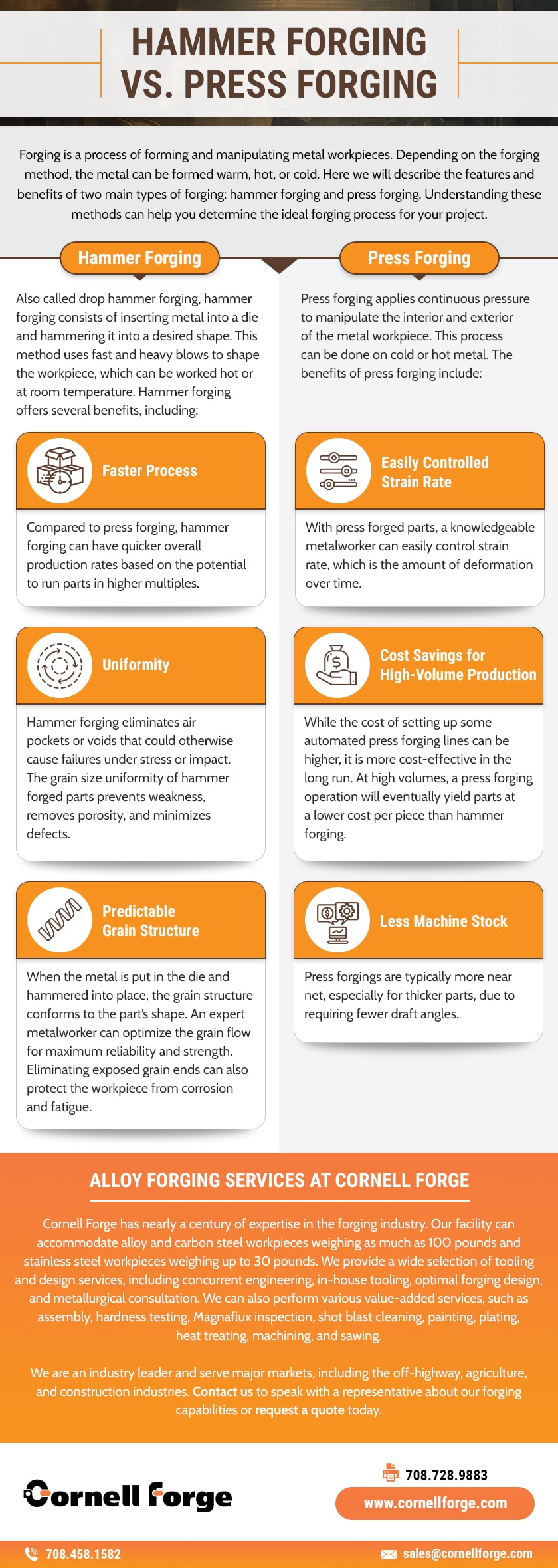

Hammer Forging vs. Press Forging - Cornell Forge Co.

Die Forging - an overview

Open Die Forging vs. Closed Die Forging

Differences between Closed Die Forging & Open Die Forging

Forging - Definition, Diagram, Types, Tools, Operations