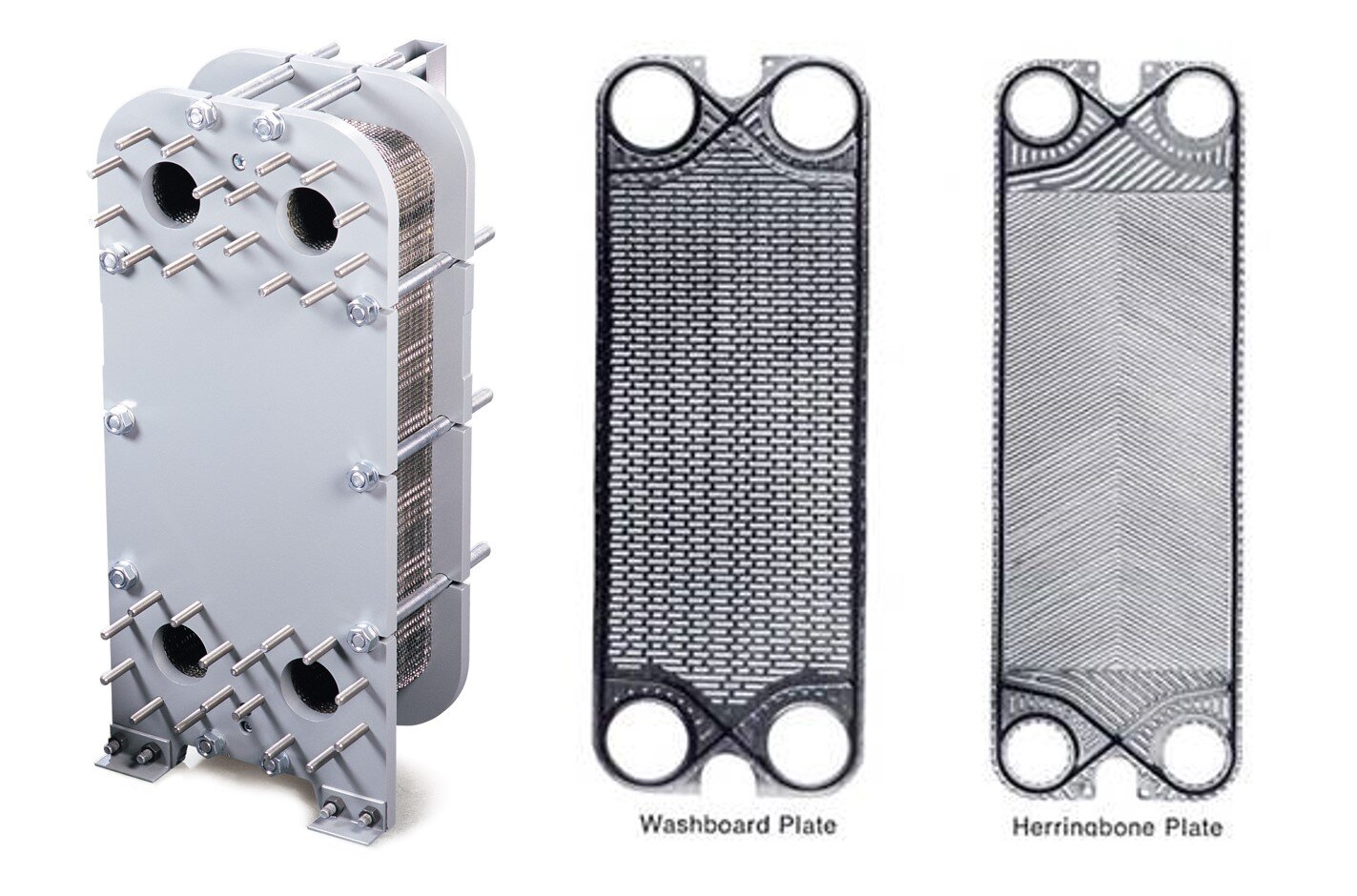

How To Size A Waterside Economizer Part 5: Why Plate & Frame Heat Exchangers Are Preferred —

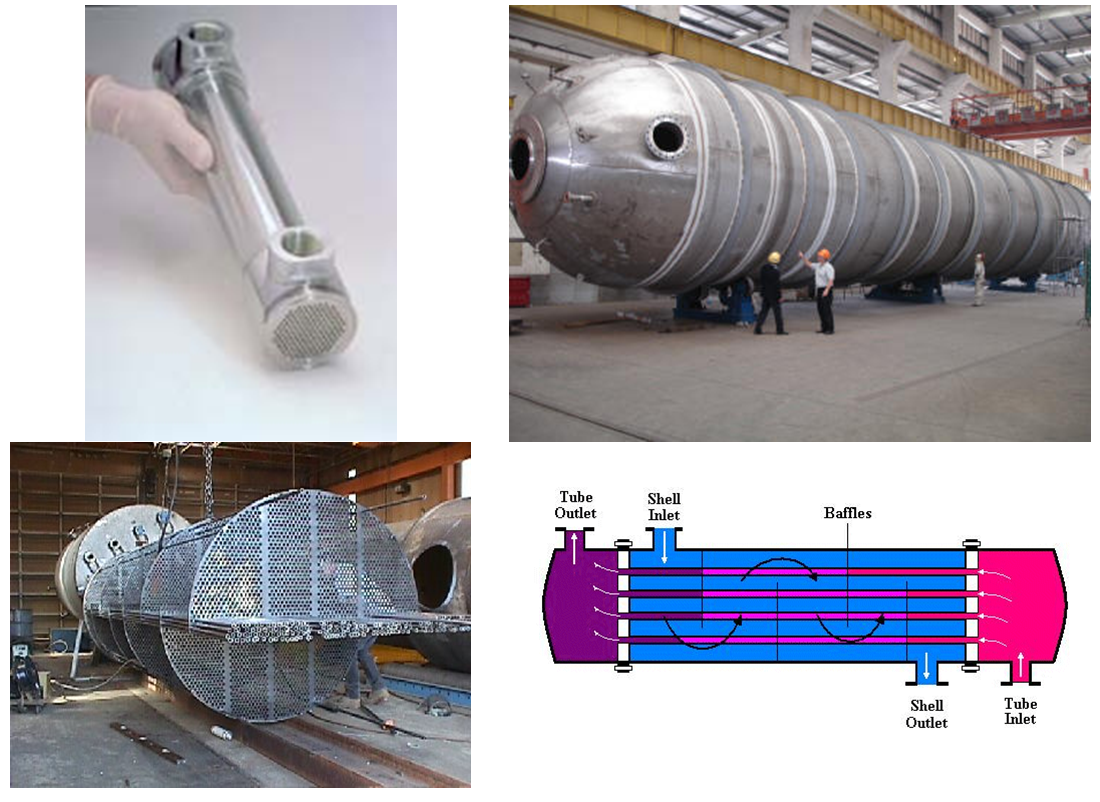

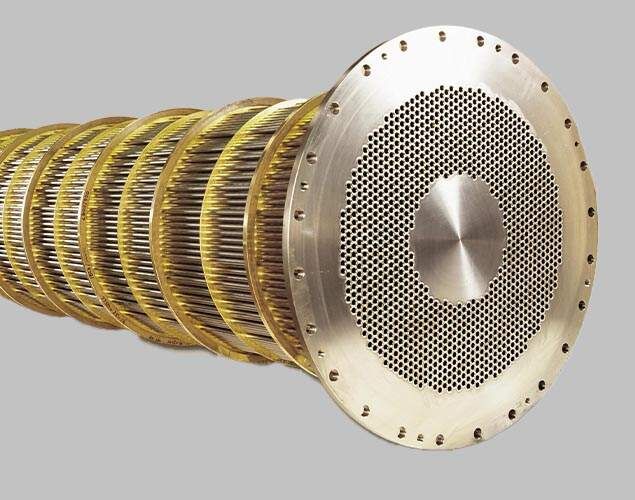

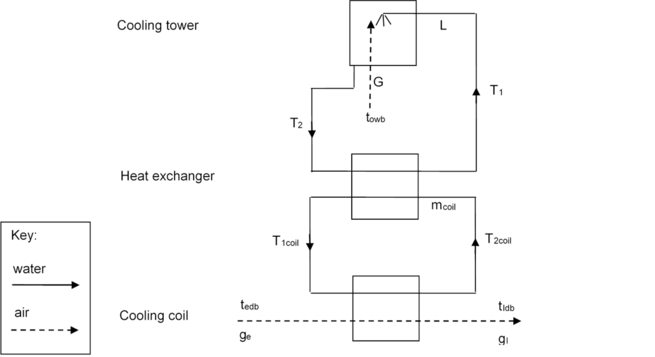

Waterside economizing typically involves the transfer of BTUs from an open loop cooling tower system to a closed loop chilled water system. Since these two hydronic systems must remain separate so we do not foul the chilled water systems, a heat exchanger is required to prevent mixing of the flu

Dedicated Waterside Economizers (types)

August, 2010

Waterside Economizing Series — HVAC Blog —

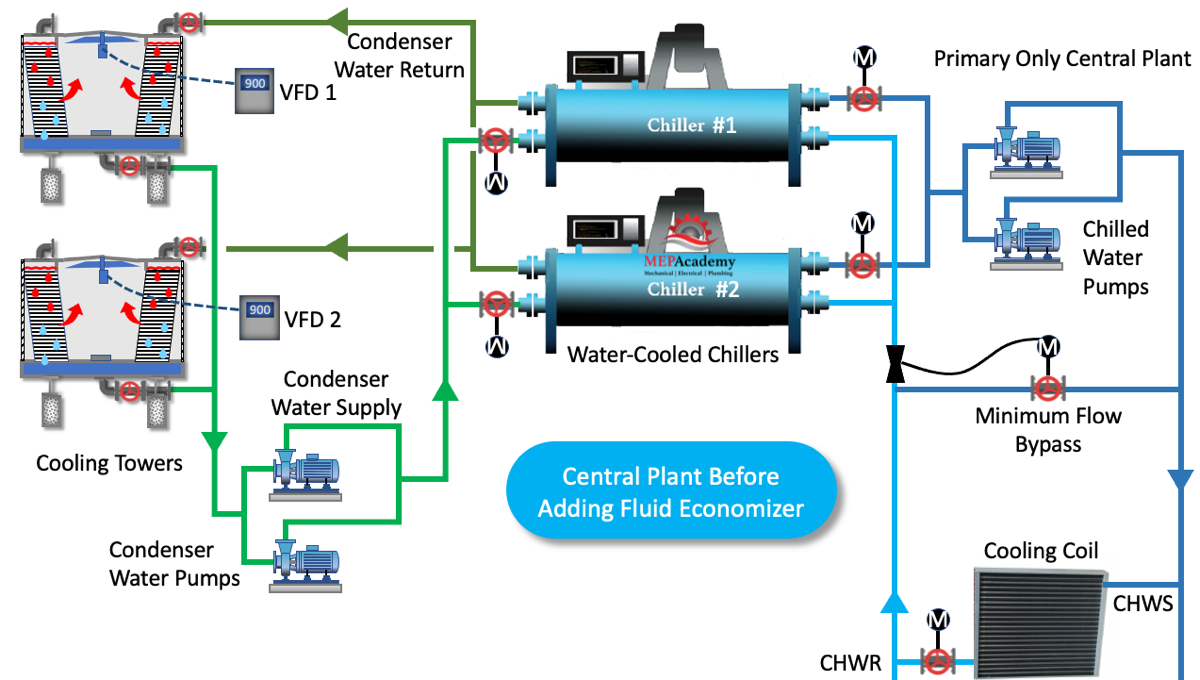

How Waterside Economizers Work - MEP Academy

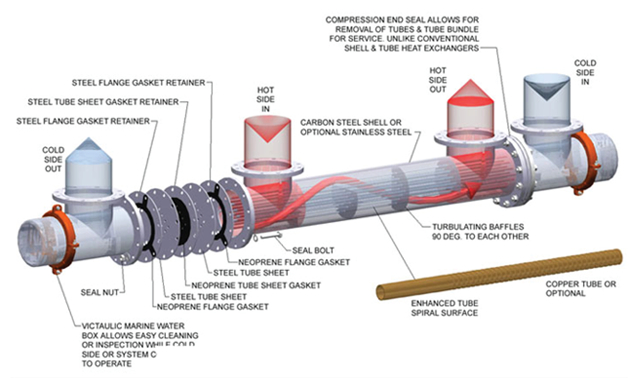

Thinking Beyond Plate & Frame Heat Exchangers for Waterside Economizing —

How To Size A Waterside Economizer Part 1: How ASHRAE 90.1 Updates Have (Or WILL) Change Chilled Water Design —

Waterside Economizers Part 5: Heat Exchanger Location Options

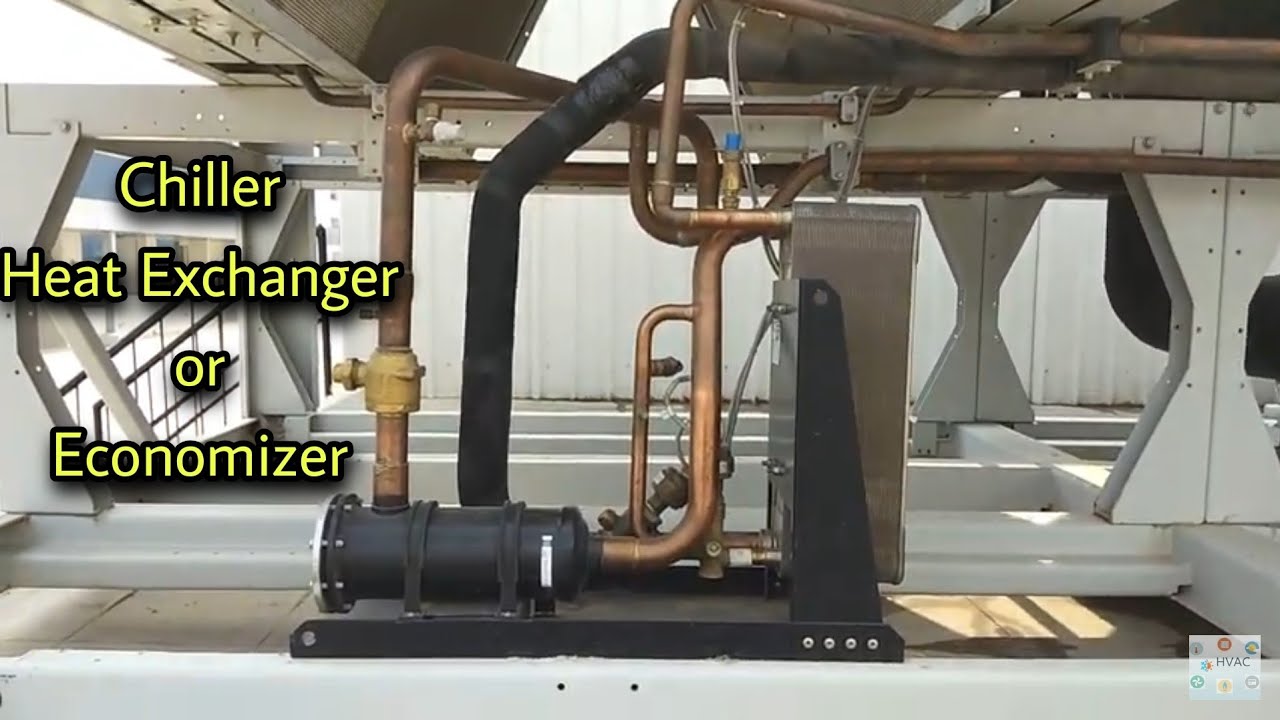

Economizer Part 05 Plate Heat Exchanger Type Economizer Sub Cooling Assembly Related#HVAC

ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 2 Condenser Water Distribution System Design, PDF, Heat Exchanger

PDF) CFD analysis of an economizer for heat transfer enhancement using serrated finned tube equipped with variable fin segments

Waterside Economizer - NYCET

Economizer Part 05 Plate Heat Exchanger Type Economizer Sub Cooling Assembly Related#HVAC

How Waterside Economizers Work - MEP Academy