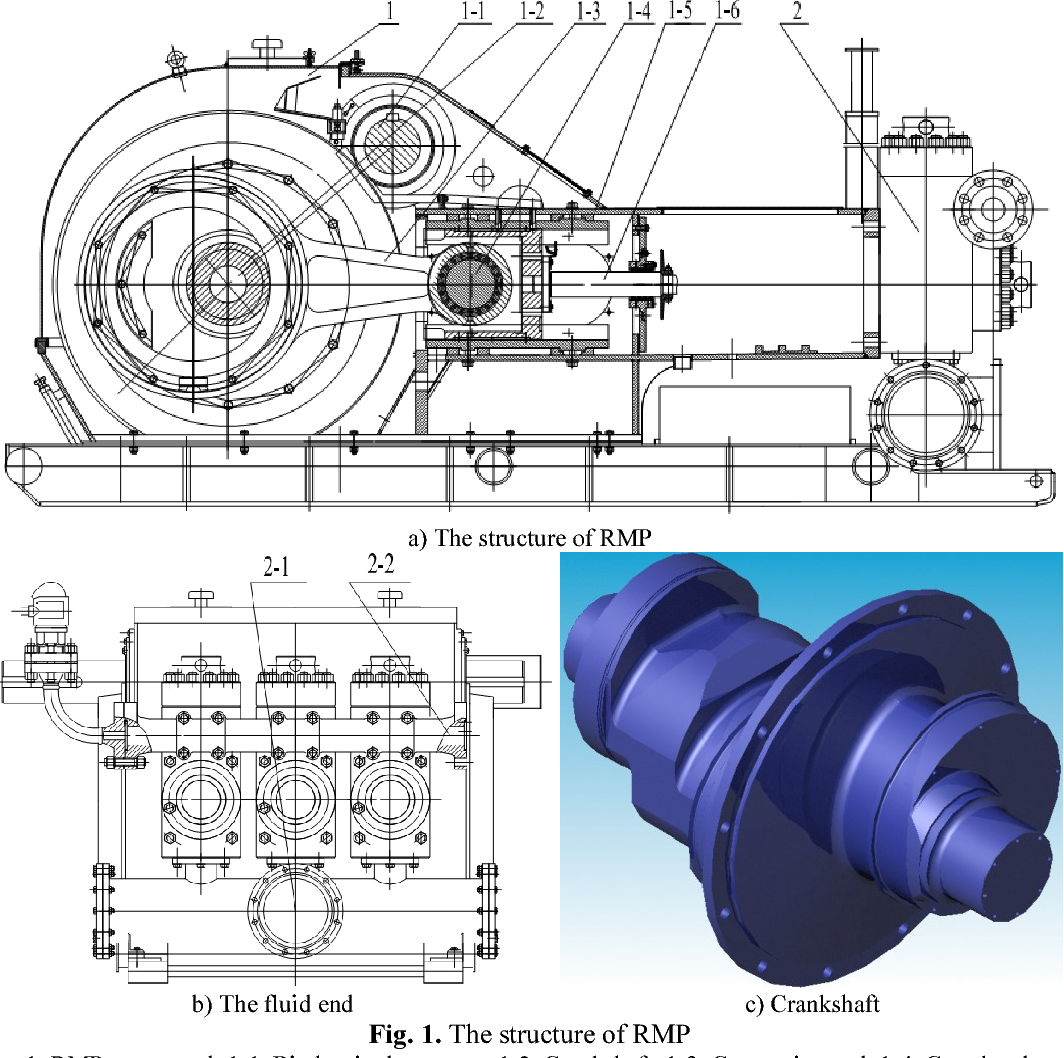

Dynamic loading and stress analysis on crankshaft of reciprocating mud pump

Computation model of crankshaft was built and the dynamic characteristics of crankshaft were studied. FEM was performed to obtain the maximum main stress, the minimum main stress and the Mises stress at three kinds of critical working conditions of crankshaft. Through movement analysis and computation for various components of reciprocating mud pump (RMP), the loads of crankshaft were obtained. The maximum stress of crankshaft at the three kinds of dangerous operating modes was obtained from the FEM stress analysis. It is located in the critical region and the location belongs to the dangerous position in most of the fracture crankshafts. The FEM stress analysis results are very valuable in guiding actual application development for intelligence optimization design of RMP.

Full article: Static and modal analysis of a crankshaft reciprocating driver for reciprocating-airfoil (RA) driven VTOL aircraft

Pump FAQs

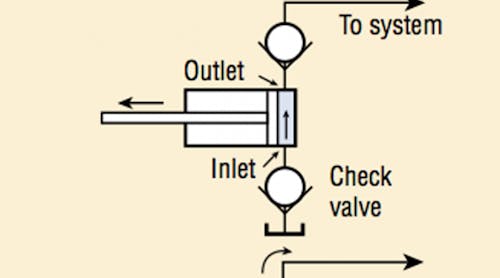

Engineering Essentials: Fundamentals of Hydraulic Pumps

NEW* 2020 Kawasaki Teryx KRX1000: First Look

Theory

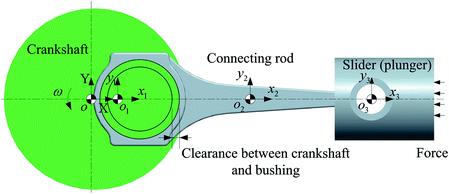

Dynamic Analysis on Crank-Connecting Rod Mechanism of Reciprocating Pumps with Crankshaft–Bushing Clearance

PDF) Design and Optimization of IC Engine Crankshaft

DOXFORD-J Type Engine

Design and analysis on the flow fluctuation of a new horizontal space multiphase crankshaft pump - Wu - 2019 - The Journal of Engineering - Wiley Online Library

Machines, Free Full-Text

Dynamic simulation and stress analysis for reciprocating compressor crankshaft - Bin-yan Yu, Quan-ke Feng, Xiao-ling Yu, 2013